Retrofit

We can help you Retrofit your tailor made needs into used CNC machine and ensure you can meet the demands of new technical challenges. Old controls can therefore be replaced quickly and simply. This will drastically reduce Investment Cost on setting up a CNC machine!

Tools Wizard Software

Characteristics of the TOOLBOX software

Graphical software for tools, adapted to any kind of CNC machine tool with at least 5 axis, freely of the level of evolution of the NC equipment. The personnel that assists the machine tool with NC can familiarize with the software in few days of training.

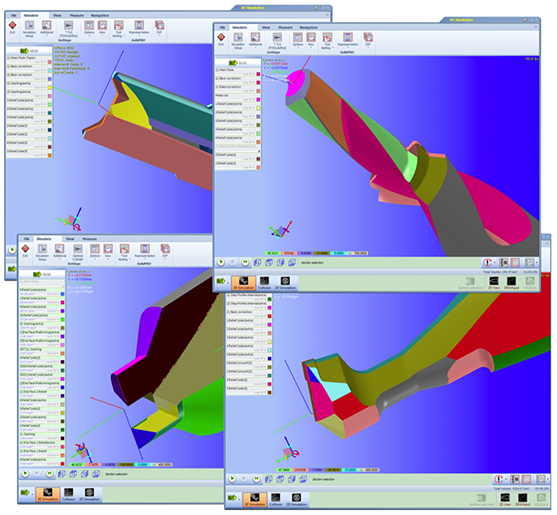

Toolbox software structure

The application has a tree structure, in which the compound elements open and close according to the user intention to introduce or to trace information. The corresponding parameters of the tool are structured on operations, providing a quick access to the desired information. For every operation in the tree we have attached the following groups of information: specific processing options, geometry, kinematics, technology of processing, definition of the working cycles, corrections, specific technological parameters, the technique of input and output from processing. For the treatment operations of the flute, there is the supplementary possibility of calculating the form of the abrasive wheel starting from the theoretical form of the groove.

Definition of the tool

The modular structure of application allows the definition of various configurations of the tool’s form: - head (milling cutter, twist drill, deep hole drill, spherical, radius, tapered); - body (cylindrical or tapered milling cutter, step drill, staggered tooth cutters, form cutters, taps). By combining these configurations (drills, milling cutters) special tools can be obtained. The tools can be with left or right hand helix and with cutting part on the left or right. The simulation can be performed in continuous or step by step mode, the colors of simulation steps being freely defined for every operation. The division of the tooth can be equal or unequal. For every type of body can be executed various types of flutes (one or more for every tooth). The head geometry can be of standard type or free.

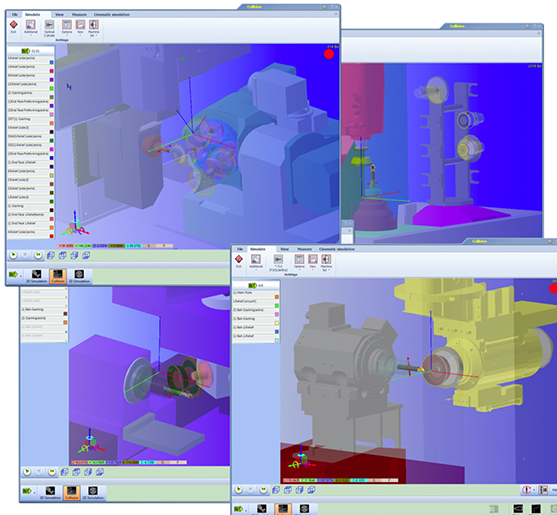

Retrofit Machine

Not everyone can purchase a new CNC machine due to the high cost of these machines. On the flip side, CNC machines have robust mechanics and long-life and that is why many CNC machines have been successfully running for decades.

In most of these machines, after ten years, the risk of failure to the controls and electronic components increases. Also, because the Technology would have advanced so much in these years, fixing these old Controls and components have become increasingly expensive.

To cater to these problems, we can help you Retrofit your tailor made needs into used CNC machine and ensure you can meet the demands of new technical challenges. Old CNC controls can therefore be replaced quickly and simply. This will drastically reduce Investment Cost on setting up a CNC machine!

We welcome you to visit our facility to view successfully installed Tool Grinding Application software.